|

|

The Model 2150 CNC DedTru is a precision 3-Axis CNC grinding system for centerless OD grinding. All of the DedTru CNC Grinding Systems combine the use of Unison's proprietary software/Machine Control.

The Model 2150 combines the use of Unison's proprietary software with our DedTru fixtures allowing the machine to perform throughfeed, infeed, secondary operation, tapers and profile chamfers for cylindrical parts from 0.001 inch to 5 inch diameter. These CNC Grinders are ideal for prepping blanks used in manufacturing of precision cutting tools. |

Unison's CNC DedTru Grinding Systems are constructed on a cast iron base which has been hand scraped to insure the highest level of accuracy. The Model 2150's are designed with a hole through the column housing for easy removal of completed parts as well as allows for the grinding of longer parts. All Model 2150's are constructed with precision ballscrews to increase both the accuracy and longevity of our machines. A closed loop positioning system is standard on all our FGS (Flexible Grinding System) machines which provide feedback to the motion control to maintain accuracy at all times. Over the years, as the machine's components wear, this system automatically compensates for such wear allowing you to consistently grind accurate parts.

Our FGS machines have the capability to dress grinding wheels on the machine with a wide range of dressing options and, as an added benefit, our software automatically compensates as the grinding wheel wears. The software also allows you to dress forms in the grinding wheel using a Single Point Diamond, Dual Point Diamond and/or Electric Roll Dresser. Unison's software is easy to learn and a complete package is installed on every machine which allows our customers to use the Model 2150's for additional applications at a later date without incurring any further software charges. Our software package is highly versatile and includes applications for ID Grinding, ID Profile Grinding, Surface Profile Grinding, Plunge Grinding, Mulitistep Grinding, OD Profile Grinding, Throughfeed Grinding, Standard Surface Grinding and the ability to mix these modes in one cycle start.

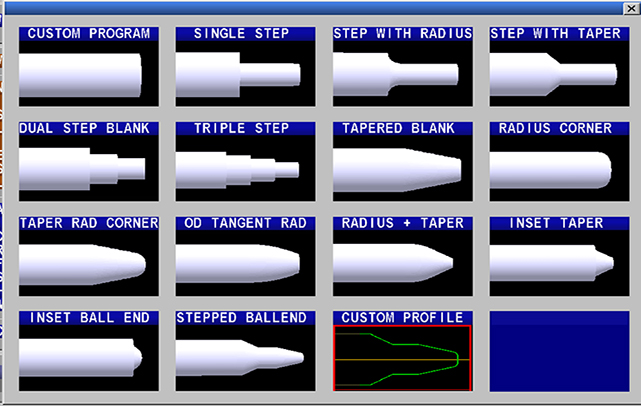

BLANK PREPARATION MADE SIMPLE

The Model 2150 is ideal for prepping blanks used in the manufacturing of precision cutting tools. With the introduction of Version 7, Unison Corporation has once again set a new standard in the ease-of-use of software by simplifying the most complex blank geometry. |

|

STANDARD SOFTWARE CYCLES INCLUDE

- Centerless Through Feed Grinding Centerless Plunge Multiple Step Centerless Plunge Grinding Profile Plunge Centerless Grinding

- Centerless OD Profile Grinding

|

- Centerless ID Grinding

- Centerless ID Profile Grinding

- Standard Surface Grinding

- Creep feed Grinding

- Peel Grinding

|

| APPROXIMATE AXIS TRAVEL AND DEFINITION |

Vertical

Travel

Drive

Feedback

Feedrates |

"Z" Axis

5" [

AC or DC Servo Motor

Precision Ballscrew

Glass Scale .00002" resolution

Closed Loop

0-3.0 ips [0-75mps]

Programmable

|

Longitudinal

Travel

Drive

Feedback

Feedrates |

"X" Axis

18.0"

AC or DC Servo Motor

Precision Ballscrew

Rotary Encoder .00002" resolution

Closed Loop

0-6.0 ips [0-150 mps]

Programmable

|

Cross

Travel

Drive

Feedback

Feedrates |

"Y" Axis

5" [127mm]

AC or DC Servo Motor

Precision Ballscrew

Glass Scale .00002"resolution

Closed Loop

0-6ips [0-150mm]

Programmable

|

| |

|

| |

|

|